Description

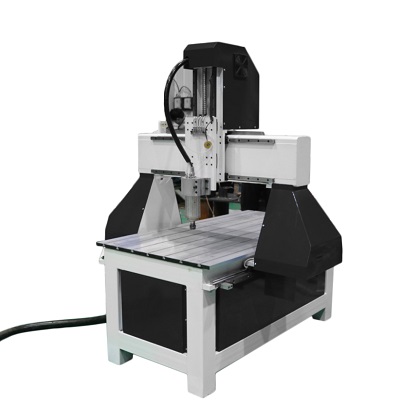

Automating the Future of NZ Housing: The Heliner Bespoke CNC Wall Panel Center

The Solution

Bridging the Gap in Off-Site Manufacturing (OSM) With the 2026 “Granny Flat” exemptions and the rising demand for minor dwellings, New Zealand builders need speed. However, most international machinery is built for mass production—rigid, expensive, and unable to handle custom designs.

The Heliner Nailing & Trimming Center is a hybrid solution. It allows your team to focus on the craftsmanship of the frame, while our CNC technology handles the repetitive, precision-heavy task of skinning, nailing, and trimming.

How It Works

Designed for the “Batch of One” Workflow Our flat-bed system integrates seamlessly into your existing production line:

-

Manual Frame Assembly: Lay your timber frame (90mm or 140mm) on our heavy-duty table.

-

Automated Nailing: Using industrial auto-nailing guns, the gantry executes G-code patterns to secure panels to the top surface with 100% accuracy.

-

Precision Trimming: An on-board power router spindle follows the nailing process to trim overhanging edges and cut out window/door openings instantly.

Key Technical Specifications

| Feature | Specification |

| Control System | Full G-Code Compatibility (Suits most NZ Design Software) |

| Tooling | Dual-Head: Industrial Auto-Nailer + High-Torque Router Spindle |

| Table Size | Fully Customizable (Standard NZ Prefab size: 3.5m x 13m) |

| Materials | Timber Framing, SIPs, Plywood, OSB, MgO Board, Plasterboard |

| Lead Time | 6 Months (Bespoke build to your workshop requirements) |

Why Heliner?

-

Not a “Fixed Program”: Unlike mass-market machines, our system is fully programmable. Change a window size or wall height in seconds.

-

Built for NZ Standards: Designed to handle the high-performance 140mm framing common in modern NZ builds.

-

Local Support: Engineering support and parts are managed directly from our Gracefield, Lower Hutt headquarters.