Uncategorized

Acrylonitrile butadiene styrene (ABS) plastic is made from oil-based resources and is known for its impact resistance and toughness. Compared to PLA, ABS has a much higher melting temperature. Due to its higher melting point, ABS has to be printed at a higher temperature of around 240 to 260 degrees Celsius at nozzle temperature.

Polylactic acid (PLA) plastic is created from renewable resources, such as corn starch, tapioca roots or sugarcane. It is biodegradable and is widely used in packaging for items like food products. PLA is more brittle than ABS and due to its biodegradability PLA components have a shorter lifespan than ABS when subjected to harsher conditions. PLA is slightly easier to print with than ABS due to its lower print temperature and its ability to print on and stick onto an unheated print platform. Additionally, PLA filament can print at higher speeds.

Both ABS and PLA can produce dimensionally accurate parts and most people would have trouble distinguishing the better print. But ABS’s biggest disadvantage when it comes to print quality is its tendency to curl and warp at the bottom, or even sometimes in the middle of the print. ABS also has more trouble when it comes to finer details like sharp corners, which will often be printed with a slight rounded edge. To improve ABS prints, many people use a method of bathing their prints in an Acetone bath or Acetone vapour. This smooth’s out the print lines and gives a glossy, shiny appearance. Compared to ABS, PLA exhibits much less print warping. Because it undergoes more of a phase-change than ABS, it can also print much finer details. Active cooling enables PLA to print much sharper corners without the risk of curling, warping and cracking. PLA can also be printer at a higher flow rate, which leads to stronger over layer bonds. ABS components are still stronger due to the plastic’s mechanical properties.

ABS – plastic is made up of three main components which release tiny particles into the environment when heated. These particles can be potentially harmful to those breathing them in.

PLA – Because PLA is made from natural materials such corn it does not release the same sort of toxic smell that ABS emits.

Both ABS and PLA absorb moisture from the air if they are not stored properly. However your filament is not going to be ruined in a couple of days and moisture can be removed by drying it with the likes of a food dehydrator or oven. Preventing moisture absorption can be achieved by placing you filament in a sealed container or bag.

Project Introduction

When crafting with FDM printer, designers sometimes will feel bound by the material. Currently, FDM printer mainly uses thermoplastic as raw material to print stuff and the surface texture is always the same. However, with post process, the printed model can be more colorful and even has a metal texture.

Print the model

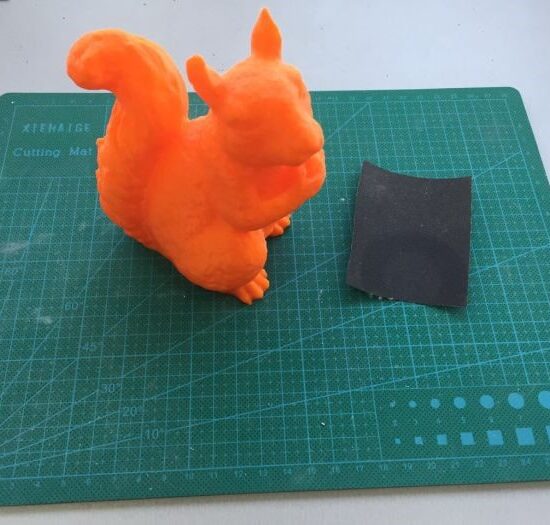

For this project, we use a squirrel model as an example. After sliced by 3DStar software, the model was saved in a USB drive and load into the Einstart-C printer. Couple of hours later, a beautiful squirrel was printed and ready for post process.

Polish the Surface

Surface polish is necessary for later coloring. A fine sand paper can help smooth the surface.

Coloring

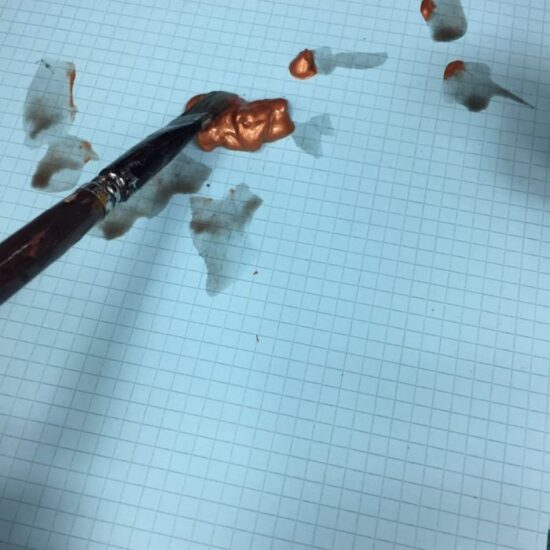

Acrylic paint was used for coloring in this project. It has a strong bond with the PLA model surface. To paint the model, the first step is to apply a black base. Use black acrylic paint to cover the whole model evenly.

Wait for the base paint to dry and then apply bronze paint. Dry up the bronze paint a little bit before painted onto the model. This will prevent the paint flowing into detailed place and ruin the texture. Gently brush the surface so that the paint only apply to the protruding area.

Finally, apply varnish paint to shine the surface and create a metal reflective effect. Also, varnish can help protect other paint layers.

With post process, it is possible to use a low-cost desktop printer to create wonderful art with different textures.

Project Introduction

In STEAM education, students’ interest is one of the key things that teacher have to grab. For example, in an art class, it will be monotonous if the educator only asks students to form a sculpture since students will not be able to receive any reward to memorizing their hard work. With the help of 3D scanning and 3D printing, students now can make a sculpture, scan it to get a digital model and then transform it to a pen holder or other useful objects. In this way, students will be able to explore and test their skills in varieties of aspects including creativity, technical skill, and aesthetic ability.

Make the Sculpture

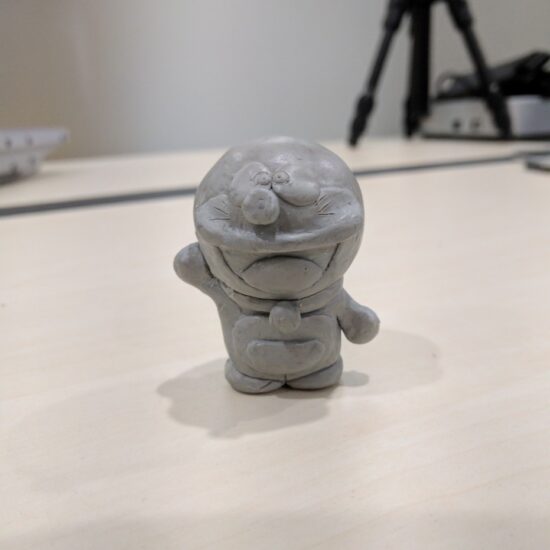

Students can use play dough or clay to form any character they like. It could be animals, cartoon characters or other objects that they are familiar with. For instance, one of the students made a sculpture based on a cartoon character with clay.

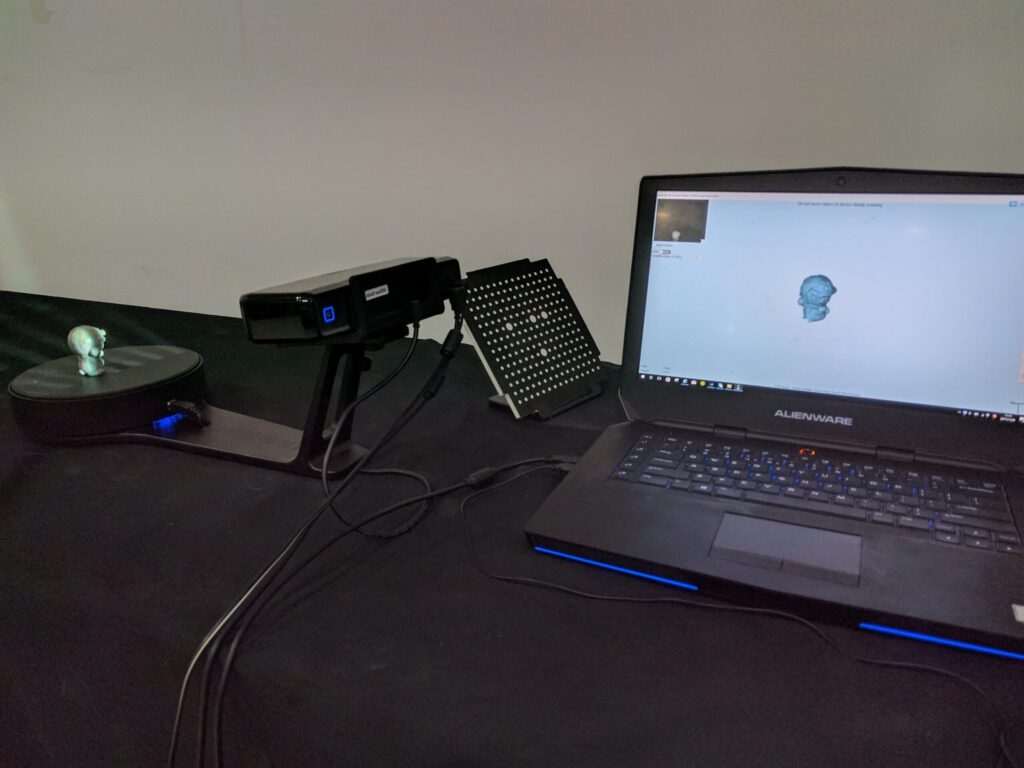

Scan Sculptures

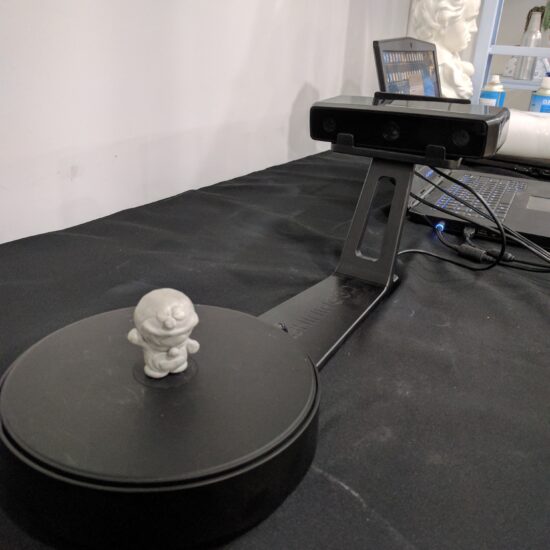

After the sculpture was made, the next step is to digitalize the sculpture. An Einscan-SE 3D scanner was used to scan the sculpture and generate a digital model. This will allow us to edit the sculpture with 3D modeling software in order to smooth the surface and add more features that are hard to shape with hands.

Modify the Model

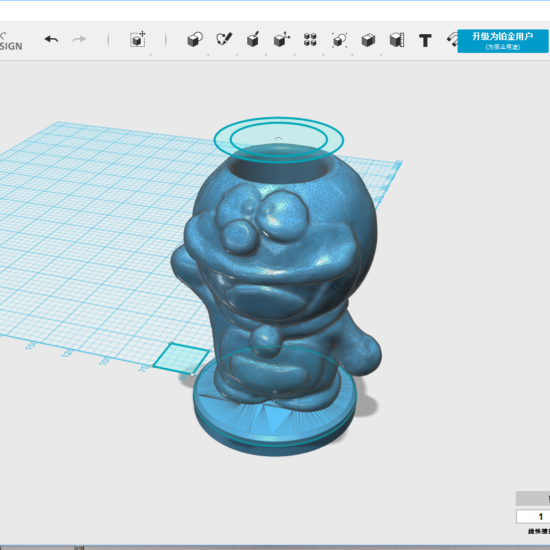

The generated digital model was then loaded into 3D modeling software for modification. In this case, the talented student uses 123D Design from Autodesk to transform the cartoon character into a pen holder by adding a base and carving a hole from the top.

Print the Object

Finally, the designed object model was sliced and printed by the Einstart-C desktop 3D printer. The printing process was easy and quick: just process the .stl model file with 3Dstar software then transfer the generated model file with a USB drive to the printer and hit start print. The printing speed of Einstart-C is faster than other similar printers. The whole model is 123mm high and only took about 7 hours to print which is almost half of what it took for the former model.

With the printer, students can take back a meaningful reward home quick and easy. With the printer, the STEAM class can offer both depths of knowledge and joys of design.