Description

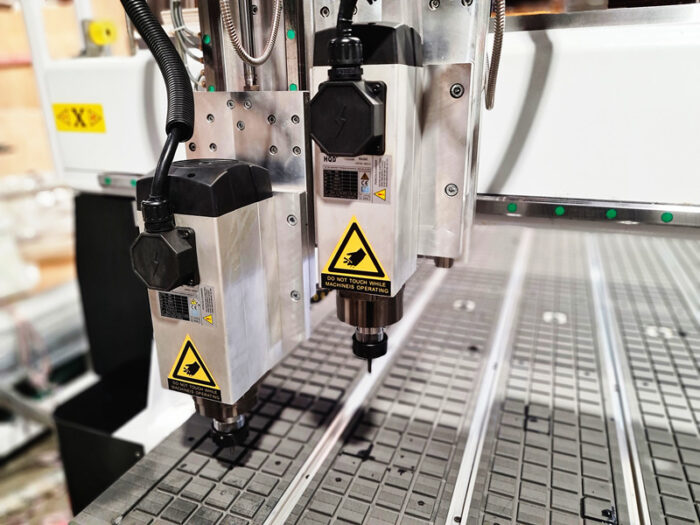

Introducing the H-1325Ax Multi-Spindle CNC Router

For those in search of efficiency in CNC machining, the H-1325Ax Multi-Spindle CNC Router stands out. This CNC machine supports up to three spindles. Each spindle holds a different tool, and all three operate on the job from a single program file. Instead of switching tools, this CNC router switches spindles, making it faster and cheaper than auto tool change machines.

Many jobs, particularly in the woodworking industry only require 2-3 tools. This CNC router is therefore an optimal choice for mass production applications in New Zealand.

If your job requires more than 3 tools, then the Auto Tool Change CNC Router might be a better fit for your application. Check out the following link for the H-1325AC Auto Tool Change CNC Router.

We have shipped this machine to happy clients. Check this out and other stories on our LinkedIn

SPECIFICATIONS (DEFAULT)

| Working Area | X 1300mm x Y2500mm x Z300mm |

| Spindle | Choose from one to three air cooling spindles (customizable) |

| Axis | X, Y and Z |

| Spindle Power | Choose from 3.5kw to 6kw (customizable) |

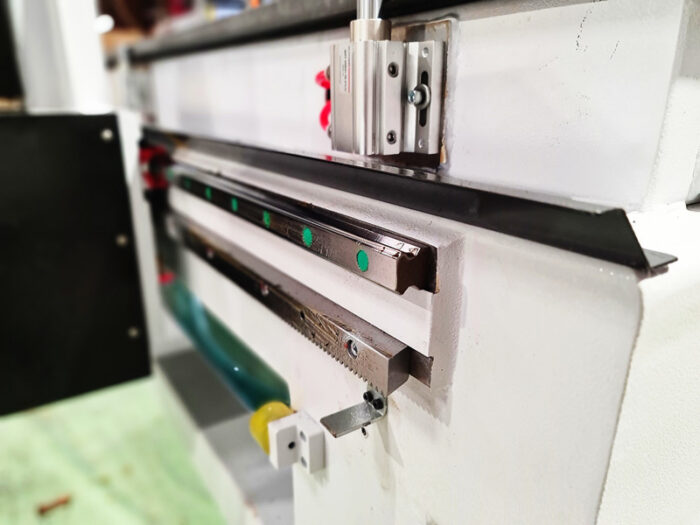

| Table | Vacuum table (6 independent channels) + T slots |

| Control System | Heliner MDRCNC |

| Motor and Driver | Hybrid Servo Motor |

| Repeat accuracy | ±0.025mm |

| Speed | Max feed rate 30m/min |

| Power | 415V, 3-Phase |

| Weight | 1500kg |

| Other features | Auto lubricant system, Auto tool height measure, Low-pressure alarm |

| Safety | Multiple Emergency Stops Spindle Safety Guard and Dust Enclosure Safety Light Curtain (optional) All parts compliant with AS/NZS Safety Standards Installation procedures compliant with Worksafe NZ. |